Generac Industrial Power Industrial Strength

Choices to Meet Your Power Generation Needs

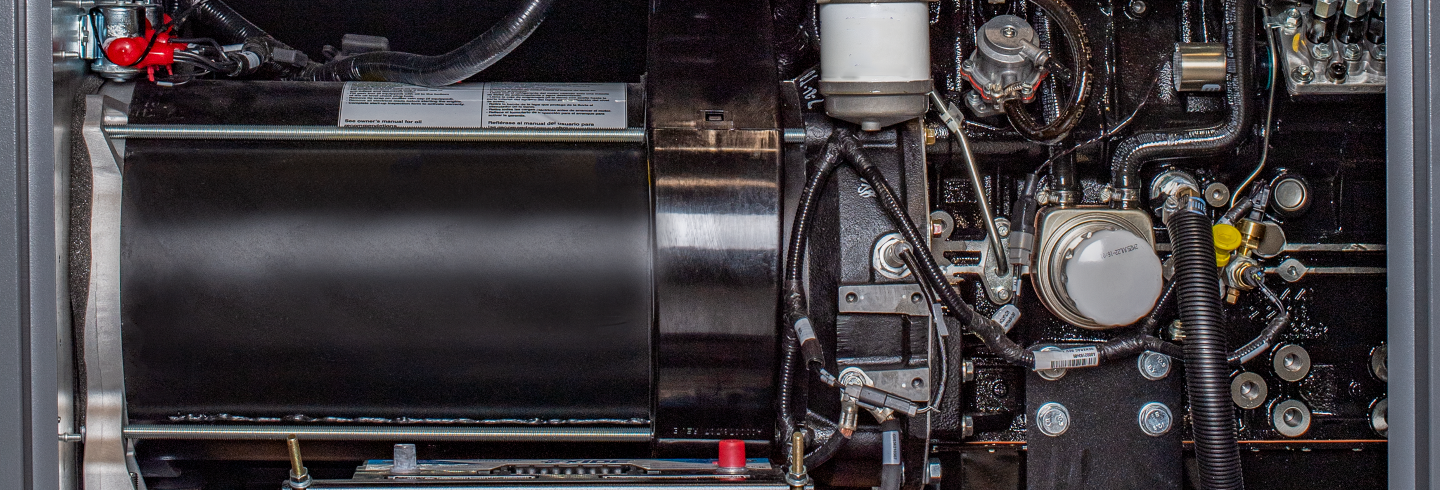

Generac Industrial Power designs, engineers, and manufactures our products in Wisconsin, United States. From start to finish, we have the hardest working team in the business, making sure you have the best available product on the market. We take pride in the details. Every step of the process is completed with the customer in mind. Our team designs market leading innovations and builds each part, making sure it works when you need it most.

-

Engineering

-

Design

-

Manufacturing

Engineer

Engineers at Generac Industrial Power focus on the design and operation of the integrated systems for the production of our generator systems. Our primary focus is to turn raw material into an updated product in the most effective, efficient and economical way possible.

Our engineers must ensure that the generators and the building electrical systems they support are appropriate for the specific application. Whether providing standby power for health care facilities or data centers, engineers must make decisions regarding generator sizing, load types, paralleling, fuel storage, switching scenarios, and many other criteria.

Engineers at Generac Industrial Power take the latest designs and ideas and make them a reality. Our engineers apply the knowledge of the product design and we choose the best technologies and processes to manufacture our products, plan and design the factory that will produce them and manage the running and maintenance and continuous improvement of the entire process.

Design

Our design engineers study, research and develop ideas for new products and the systems that make them. We are not only concerned with making products that look good and are easy and safe to use, we are also concerned with ensuring products can be made cost-effectively and efficiently.

Typical Tasks for a Generac Design Engineer:

- Think up possible power solutions

- Research if the design will work and be cost-effective for the customer

- Assess the usability, environmental impact and safety of the possible solution

- Use computer-aided design (CAD) and computer-assisted engineering (CAE) software to create prototypes

- Collect and analyze data from prototypes

- Modify designs and retest

When designing generator systems, engineers must ensure the generators and the building electrical systems they support are appropriate for the application. Many questions must be addressed before starting the generator system design. Most of these questions are related to the application and the site operating conditions, which drives the selection of the different generator system components and their characteristics.

Design Considerations:

- Code compliant

- Location of generator system

- Load types and electrical characteristics

- Engine-generator system

- Transfer switches

- Paralleling

- Generator sizing

Manufacture

Our team transforms raw materials into finished goods on a large scale. The process begins with the product design and materials specification from which the generator system is made. The raw materials are then modified through processes to become the required part before being assembled.

Chances are, as a customer, you do not spend a lot of time thinking about who makes your generator system, but we do. Our team works hard every day to refine and process raw materials into something useful, backup power. We specialize in the skills required for mass production. Our assembly lines allow us to create parts the can be used interchangeably and allow finished products to be made more readily. Our technology has made our manufacturing work more efficient and has helped our workers be more productive.