Diesel-fueled generators, a common solution used in many different commercial and industrial applications, come with a bulky burden: fuel storage. On the other hand, natural gas emergency standby generators do not require on-site fuel storage, as the fuel line is connected to the natural gas utility grid. This always-on connection to the fuel source eliminates the fuel storage dilemma. It also adds a layer of reliability, given the natural gas infrastructure and its supply system is so seldom interrupted. Generac is one of the top natural gas generator manufacturers.

When it comes to diesel generator units, the fuel burden begins with the diesel generator fuel tank — or tanks — and their associated purchase and installation costs. Many diesel generators sit atop a base tank, storing enough fuel to run the generator at full load for 24-72 hours. For larger generators, this can amount to thousands of gallons of fuel. There are a number of decisions that need to be made when considering the generator’s fuel supply system — most notably the space or square footage available for this fuel storage. Not all facilities have the luxury of extra space for large diesel tank placements, so creative options must be sought. Other factors, such as local building codes and environmental issues specific to diesel fuel storage and spill mitigation, should also be examined.

Additionally, on-site diesel fuel storage entails recurring costs not associated with a gaseous-fueled solution. On-site fuel storage requires that a facility manager keep the storage tank(s) full and schedule diesel fuel deliveries. During more extreme or dire times of need, such as during prolonged outages, securing emergency diesel fuel deliveries can become an added liability. As natural gas is utility-supplied, it is always available — no fuel deliveries are needed. For this reason, many choose a natural gas solution generator or genset solution.

The facility manager is also responsible for maintaining the quality of the fuel and tank, scheduling regular maintenance and inspecting the fuel system at regular intervals, all of which takes time and adds to the total cost of ownership. Because stored diesel fuel has a shelf life of between 12 and 16 months before it begins to degrade, fuel maintenance — also called fuel polishing — is required. Fuel polishing removes water, organic growth due to bacteria and fungi and any dirt and debris from the fuel that would clog or otherwise impair the fuel system. If debris from degraded diesel fuel gets into the engine, it will cause costly engine damage that requires repair.

All of these costs and efforts can be avoided with a natural gas solution. Natural gas is the more dependable and less expensive fuel over time when compared to diesel, requiring less overall maintenance and attention from a facility manager. This allows more time to focus on keeping other parts of the business’s facility maintained. Choosing natural gas as a generator fuel allows business owners and facility managers to lift the weight and cost of onsite diesel fuel storage off their shoulders.

Related Articles

- A Matter of Time: Factors that Add Up to Time Savings with Natural Gas Generators

Whitepapers

Generac provides a variety of whitepapers to help industry professionals understand which factors need to be considered when selecting the right standby power system for each unique application.

Natural Gas Resources

Natural gas is becoming the preferred solution in many applications as it provides much longer runtimes, the permitting is easier, and lower emissions.

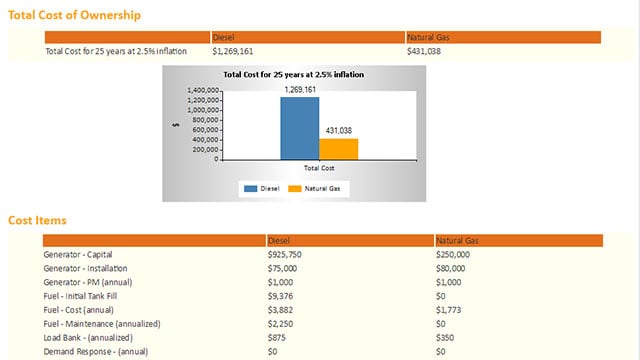

Total Cost of Ownership

Generac has made a fully customizable total cost of ownership tool to perform your own customized analysis for your unique situation.