Clean & Reliable

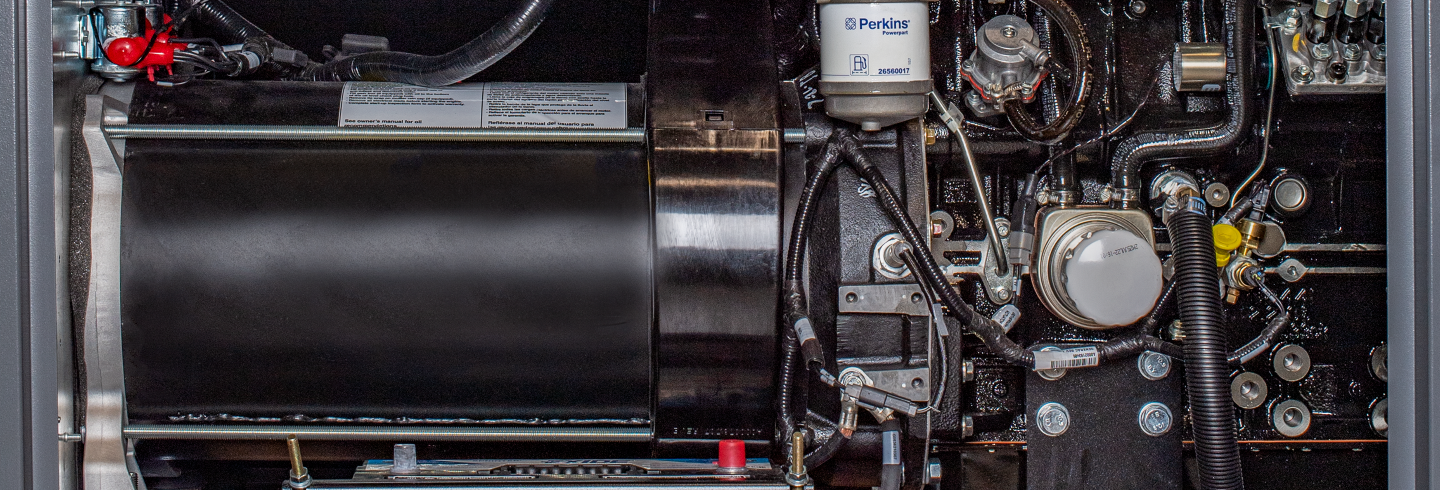

Working with natural gas was somewhat problematic until a few years ago when new technologies increased the durability and reliability of these gensets.

Natural gas generators have a comparatively limited power output. This means an individual natural gas generator generally cannot match the wattage of its diesel counterpart. However, when you install multiple natural gas generators together in parallel configuration or genset, not only can they produce a comparable or even greater amount of power, they also offer flexibility, scalability, and numerous additional benefits detailed below.

- Easier Permitting: Natural gas is a clean burning fuel that does not require excessive testing or permitting. The high level of emissions produced by diesel generators often increases the difficulty in procuring an air-quality permit.

- Long Run Times During Outages: Since natural gas is supplied by a utility with underground pipelines, it is rarely impacted by weather and the flow of fuel is largely secure—they can often run for weeks and months. For diesel generators, the fuel supply typically ends after three days. During a crisis, fuel deliveries are often delayed or non-existent.

- Low Maintenance: In diesel generators, the required low sulfur diesel gas needs to be re-conditioned or polished every 12-16 months to ensure impurities don’t affect fuel flow. This is not an issue with natural gas.

- Cost-effective Engines: Automotive-style spark-ignited engines are readily available in high volumes, making them more economical than similarly sized diesel engines.

- Reliable Fuel Supply: With diesel fuel, winter storms or unexpected disasters can wreak havoc on operations across the country. If supply trucks are delayed, it can greatly impact production.

- Overall Eco-friendliness: Many companies are becoming very “green” and considering that aspect in every part of new construction or as they remodel. Natural gas is the cleanest burning fossil fuel today; it produces the fewest emissions, and has a much smaller carbon footprint. Natural gas generators also avoid the fuel containment, spillage, and environmental concerns associated with storing diesel fuel.